DAL-e Delivery robot (Hyundai Motor)

DAL-e Delivery robot (Hyundai Motor) LAS VEGAS, January 09 (AJP) -South Korea’s Hyundai Motor Group has developed an in-house artificial intelligence chip for its mobility platform, extending its ambitions in robotics and so-called “physical AI.”

Hyundai Motor and Kia said they have completed development of an on-device AI chip for robots and are preparing for mass production, marking a strategic shift toward greater vertical integration in next-generation mobility technologies.

The automakers’ Robotics Lab said Thursday, local time, that the chip was co-developed with Korea-based AI semiconductor startup DeepX and unveiled at CES 2026 Foundry in Las Vegas.

CES Foundry is a newly introduced program at this year’s CES, designed to foster broader discussion around artificial intelligence, blockchain and quantum technologies.

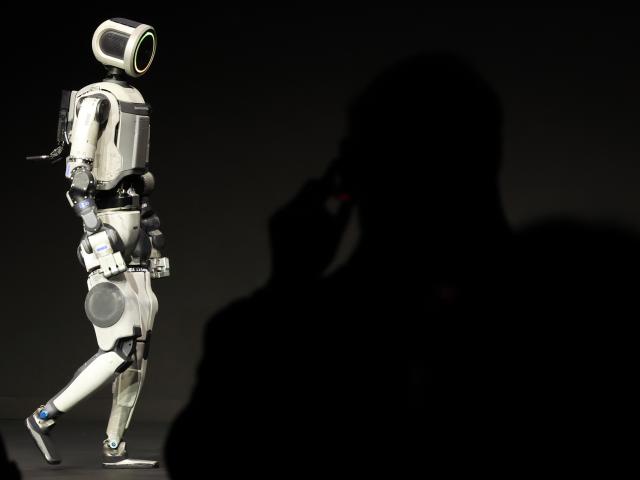

Hyundai Motor humanoid robot "Atlas" developed by Boston Dynamics takes the stage at CES on Jan. 7, 2026 (Yonhap)

Hyundai Motor humanoid robot "Atlas" developed by Boston Dynamics takes the stage at CES on Jan. 7, 2026 (Yonhap) According to the lab, the on-device AI chip consumes less than 5 watts of power and is capable of real-time data processing for recognition and decision-making. Unlike cloud-based AI systems, it operates independently of network connectivity, allowing robots to function reliably in environments where connections are unstable or unavailable, such as underground parking garages and logistics centers. The architecture also enables faster response times and offers security advantages.

Hyundai Motor–Kia said the chip supports the development of robots optimized for specific services, rather than a one-size-fits-all design. By embedding intelligence directly on the device, the companies aim to improve reliability while reducing dependence on external infrastructure.

Hyun Dong-jin, managing director and head of the Hyundai Motor–Kia Robotics Lab, said the lab is pursuing a vision of “robotizing space” to realize physical AI — intelligent machines that can perceive, reason and act autonomously in real-world environments. An internally developed AI controller has already been applied since June 2024 to facial-recognition systems and the DAL-e delivery robot at the Factorial Seongsu complex in Seoul to validate performance and quality.

The automakers said the partnership combines the Robotics Lab’s AI and software capabilities with DeepX’s semiconductor expertise, allowing them to balance cost efficiency, performance and supply-chain stability. Securing an optimized chip solution early is expected to support large-scale robot production and reduce exposure to external supply risks.

Hyundai Motor–Kia emphasized that robots must ultimately operate in everyday settings to address structural challenges such as population aging, industrial safety risks and labor shortages. The new on-device AI chip is expected to serve as a core building block for a stable physical AI infrastructure.

The group is seeking to leverage the automotive value chain it has built over decades to enable mass production of robots, while deepening cooperation with South Korea’s battery industry. Pilot projects are also under way in environments such as airports and hospitals, as part of efforts to expand applications and strengthen the country’s robotics ecosystem.

“Hyundai Motor–Kia Robotics Lab is not simply making robots; we are building a sustainable robotics ecosystem,” Hyun said. The aim, he added, is to deliver efficient, low-power robots that create tangible value for users at the final stage of the physical AI pipeline.

Lee Seong-jin 기자 leesj@ajunews.com

![[포토] 폭설에 밤 늦게까지 도로 마비](https://image.ajunews.com/content/image/2025/12/05/20251205000920610800.jpg)

![[포토] 예지원, 전통과 현대가 공존한 화보 공개](https://image.ajunews.com/content/image/2025/10/09/20251009182431778689.jpg)

![[작아진 호랑이③] 9위 추락 시 KBO 최초…승리의 여신 떠난 자리, KIA를 덮친 '우승 징크스'](http://www.sportsworldi.com/content/image/2025/09/04/20250904518238.jpg)

![[포토]두산 안재석, 관중석 들썩이게 한 끝내기 2루타](https://file.sportsseoul.com/news/cms/2025/08/28/news-p.v1.20250828.1a1c4d0be7434f6b80434dced03368c0_P1.jpg)

![블랙핑크 제니, 최강매력! [포토]](https://file.sportsseoul.com/news/cms/2025/09/05/news-p.v1.20250905.ed1b2684d2d64e359332640e38dac841_P1.jpg)

![블랙핑크 제니, 매력이 넘쳐! [포토]](https://file.sportsseoul.com/news/cms/2025/09/05/news-p.v1.20250905.c5a971a36b494f9fb24aea8cccf6816f_P1.jpg)

![[포토]첫 타석부터 안타 치는 LG 문성주](https://file.sportsseoul.com/news/cms/2025/09/02/news-p.v1.20250902.8962276ed11c468c90062ee85072fa38_P1.jpg)

![[포토] 국회 예결위 참석하는 김민석 총리](https://cphoto.asiae.co.kr/listimg_link.php?idx=2&no=2025110710410898931_1762479667.jpg)

![[포토] 발표하는 김정수 삼양식품 부회장](https://image.ajunews.com/content/image/2025/11/03/20251103114206916880.jpg)

![[포토] 박지현 '아름다운 미모'](http://www.segye.com/content/image/2025/11/19/20251119519369.jpg)

![[포토] 김고은 '단발 여신'](http://www.segye.com/content/image/2025/09/05/20250905507236.jpg)

![[포토] 키스오브라이프 하늘 '완벽한 미모'](http://www.segye.com/content/image/2025/09/05/20250905504457.jpg)

![[포토] 알리익스프레스, 광군제 앞두고 팝업스토어 오픈](https://cphoto.asiae.co.kr/listimg_link.php?idx=2&no=2025110714160199219_1762492560.jpg)

![[포토] '삼양1963 런칭 쇼케이스'](https://image.ajunews.com/content/image/2025/11/03/20251103114008977281.jpg)

![[포토] 박지현 '순백의 여신'](http://www.segye.com/content/image/2025/09/05/20250905507414.jpg)

![[포토] 언론 현업단체, "시민피해구제 확대 찬성, 권력감시 약화 반대"](https://image.ajunews.com/content/image/2025/09/05/20250905123135571578.jpg)

![[포토] 김고은 '상연 생각에 눈물이 흘러'](http://www.segye.com/content/image/2025/09/05/20250905507613.jpg)

![[포토] 아이들 소연 '매력적인 눈빛'](http://www.segye.com/content/image/2025/09/12/20250912508492.jpg)

![[포토]끝내기 안타의 기쁨을 만끽하는 두산 안재석](https://file.sportsseoul.com/news/cms/2025/08/28/news-p.v1.20250828.0df70b9fa54d4610990f1b34c08c6a63_P1.jpg)

![[포토] 한샘, '플래그십 부산센텀' 리뉴얼 오픈](https://image.ajunews.com/content/image/2025/10/31/20251031142544910604.jpg)

![[포토]두산 안재석, 연장 승부를 끝내는 2루타](https://file.sportsseoul.com/news/cms/2025/08/28/news-p.v1.20250828.b12bc405ed464d9db2c3d324c2491a1d_P1.jpg)

![[포토] 키스오브라이프 쥴리 '단발 여신'](http://www.segye.com/content/image/2025/09/05/20250905504358.jpg)

![[포토] 아홉 '신나는 컴백 무대'](http://www.segye.com/content/image/2025/11/04/20251104514134.jpg)

![[CES 2026] A tactile technology seeks to preserve Japan's endangered craft skills](https://image.ajunews.com/content/image/2026/01/09/20260109081719899487.jpg)